Tungsten electrodes

Our consultant will save your time!

Nicholas

sales department

+38 (097) 369-66-30

dignity

Tungsten electrodes are wear resistance, hardness, high melting point, Tungsten is extremely heat resistant, has a minimum evaporation rate when heated, the minimum coefficient of thermal expansion among metals, higher electrical resistance. Electrodes made of tungsten have a high modulus of tension and compression, exceptional resistance to thermal creep, good thermal conductivity. Tungsten inert in an oxygen atmosphere to 400 °C, hydrogen to 600 °C, ammonia to 700 °C, carbon monoxide to 800 °C, in concentrated solutions of acids, alkalis, Aqua Regia, boiling mercury.

DISADVANTAGES

Because of the extreme refractoriness and hardness, tungsten is poorly processed — only to achieve high temperatures. The disadvantage is the complexity of mining and obtaining it in its pure form. Under normal conditions it is hard, brittle, fragile material.

PRODUCTION

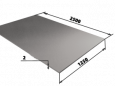

Tungsten wire and electrodes — the most demanded products of tungsten. Under normal conditions, technological plasticity of the metal is insufficient, but with increasing temperature — increased without loss of strength. That’s why hiring get hot pressure treatment. First using powder metallurgy to form the workpiece — the so-called Fort. After heating it Raskulinecz on a rotary forging machine — out electrodes (rods) section 2 — 3 mm, of which after drawing in the hot condition pull wire of minimum diameter according to GOST 25501−82. The electrode surface should be smooth, polished, without cracks, chips, burrs, grease and other defects.

welding

Tungsten electrodes are non-consumable, so for the formation of the weld pool is used a special welding wire. The tungsten electrode has a coating that stabilizes the arc. It can be acidic, alkaline, rutile or other coating, which are stabilizing, slag forming, alloying components. At the tungsten electrode rather difficult markings arc and arc unstable. To optimize the use of the zirconium additive. Such electrodes are used for welding non-ferrous metals. The electrode of EVT-15 doped with thorium, is used for welding high-alloy steels; electrodes, EVI-1, EVI-2, EVI-3 — yttrium. Argon arc welding significantly improves the quality of the weld, the electrode is protected from rapid combustion.

Electrodes in canisters for argon-arc welding table.1

| Tungsten electrodes l=175 mm in canisters of 10 pieces | ||||

|---|---|---|---|---|

| brand (color code) | diameter, mm | quantity in 1 kg | alloying elements | feature |

| WT-20 (red) | 1.6 | 151 | 1.8−2.2% (thorium dioxide) | Easy arc ignition. Well preserved form at high currents. Constant welding current. |

| 2.0 | 96 | |||

| 2.4 | 66 | |||

| 3.0 | 42 | |||

| 3.2 | 37 | |||

| 4.0 | 24 | |||

WL-20 (blue) |

1.6 | 151 | 1.8−2.2% (lanthanum oxide) | Connecting thin sheets, vysokonapornye steel, refacing valves, shapes, cutting of aluminium, copper, bronze and vysokosaharistyh steels. |

| 2.0 | 96 | |||

| 2.4 | 66 | |||

| 3.0 | 42 | |||

| 3.2 | 37 | |||

| 4.0 | 24 | |||

| WC-20 (grey) | 1.6 | 151 | 1.8−2.2% (cerium dioxide) | Stainless, acid and heat resistant steel, vysokopillya metals (molybdenum, tantalum, niobium and their alloys, copper, bronze, silicon bronze, Nickel and its alloys, titanium and its alloys). |

| 2.0 | 96 | |||

| 2.4 | 66 | |||

| 3.0 | 42 | |||

| 3.2 | 37 | |||

| 4.0 | 24 | |||

WZ8 (white) |

1.6 | 151 | 0.8% (Zirconia) | Excellent stability and arc ignition. Welding with alternating current of critical connections. |

| 2.0 | 96 | |||

| 2.4 | 66 | |||

| 3.0 | 42 | |||

| 3.2 | 37 | |||

| 4.0 | 24 | |||

WP (green) |

2.0 | 96 | Pure tungsten, the alloying elements do not exist | Zeigeist arc satisfactory, the service life is normal. Welding with alternating current (welding of Al, Mg and their alloys). |

| 2.4 | 66 | |||

| 3.0 | 42 | |||

| 3.2 | 37 | |||

| 4.0 | 24 | |||

| 5.0 | 15 | |||

WY-20 (dark blue) |

1.6 | 151 | 1.8−2.2% (yttrium oxide) | Zeigeist arc is excellent, the service life is long. The direct current welding of critical joints. |

| 2.0 | 96 | |||

| 2.4 | 66 | |||

| 3.0 | 42 | |||

| 3.2 | 37 | |||

| 4.0 | 24 | |||

domestic electrodes

The electrodes of the transmission line series are universal electrodes suitable for most alloys. Electrodes, SVI, VA, VL differ reliability and thermal stability. They are produced in any section and size according to customer’s drawings. Electrodes doped with lanthanum oxide have an easy primary and repeated the burning of the arc, steady burning, and minimal tendency to burn-through. Alloying increases the carrying capacity of the electrode and stores it in welding the initial sharpening. The electrodes of EVI-1/EVI-1 is used for welding of titanium alloys copper, low alloy, stainless steel and other steels. Doped with itrium electrode is considered the most resistant of all. It can be section of 1.6 — 4 mm, a length of 1 meter. The electrodes of the format EEP and ml are used for arc welding, cutting, spraying and welding in inert gas.

imported electrodes

Stamps WP, WL-20, WT-20, WC-20, WY-20, WZ8, are used for TIG welding. To protect also use helium or argon, pure or in mixture with hydrogen, oxygen, nitrogen, carbon dioxide. Electrodes WL-20 doped with lanthanum oxide have an easy primary and repeated the burning of the arc, steady burning, and minimal tendency to burn-through. Alloying increases the carrying capacity of the electrode and stores in its original sharpening. The electrodes WC-20 (doped with cerium) light source arc starting. They work on AC and DC, are arc stability even at low voltage and amperage. Used for welding sheet steel, orbital welding of pipelines. But when welding at high voltage oxide of cerium in a large amount accumulates at the working end of the electrode.

The recommended values of the welding current when welding in argon table. 2

| Electrode diameter, mm | A constant current, And | Alternating current, And | ||

|---|---|---|---|---|

| Straight polarity | Reverse polarity | Half wave positive less negative | The positive and negative half-cycle is equal to | |

| 1.6 | 70 — 150 | 10 — 20 | 70 — 150 | 60 — 120 |

| 2.0 | 100 — 200 | 12 — 25 | 80 — 160 | 70 — 130 |

| 2.4 | 150 — 250 | 15 — 30 | 140 — 235 | 100 — 180 |

| 3.0 | 220 — 350 | 20 — 35 | 200 — 300 | 140 — 230 |

| 3.2 | 250 — 400 | 25 — 40 | 225 — 325 | 160 — 250 |

| 4.0 | 400 — 500 | 40 — 55 | 300 — 400 | 200 — 320 |

BUY AT best PRICE

The price of tungsten electrodes depends on the brand, parameters of products and additional conditions of delivery. Tungsten hire from the «_" differs reasonable price and a wide variety of sizes that will allow any buyer to choose the option that most fully satisfies its needs. High quality workmanship and full compliance of products with the requirements of the state normative documents and technical conditions for the supply — main principle of our company in work with clients. And reasonable prices and convenient delivery method is the additional benefit of working with us.